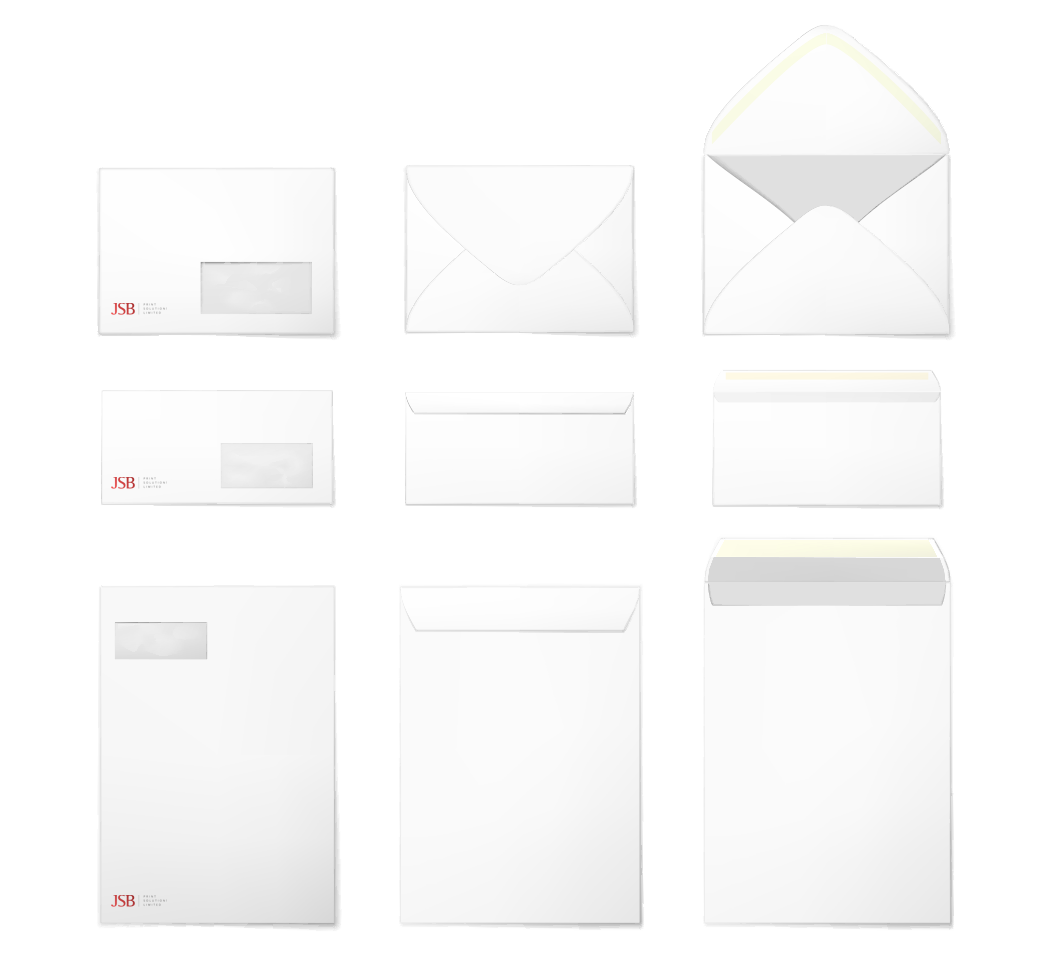

WE ARE A SUPPLIER OF PLAIN & PRINTED ENVELOPES IN NORTHAMPTON, WITH A UK NATIONAL COVERAGE.

JSB Print Solutions, established in 1984 are suppliers of standard, printed, plain and custom envelopes based in Northampton, we cover the whole of the UK.

JSB Print Solutions, established in 1984 are suppliers of standard, printed, plain and custom envelopes based in Northampton, we cover the whole of the UK.

If your requirement is for a single box of envelopes or millions of envelopes a month, we have the capacity. At market leading prices we provide a UK manufactured quality product every time. You and your mail room can rely on our excellent service.

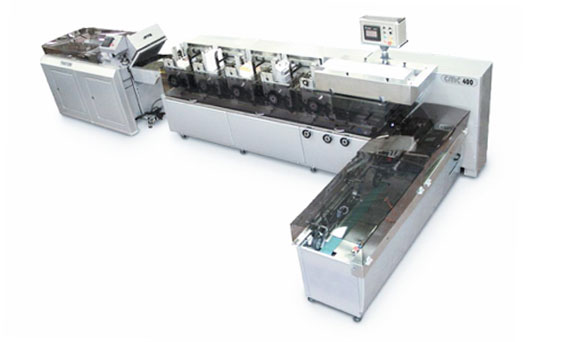

Plain envelopes, printed envelopes, custom or bespoke envelopes are the products we offer. Along with a stock management service our envelopes process through mailing and fulfilment machines every day. We are a trusted leading supplier with extensive knowledge of the manufactures of envelope mailing machines. Suited for business envelopes fulfilment machines include brands like, Neopost, Pitney Bowes, mail master and other leading envelope mailing machine manufactures.

We aim to be your first choice when selecting a supplier for all your envelope requirements.

For high volumes of envelopes with minimal print coverage – e.g. PPI, return address and small logo the print is applied in-line flexographically during manufacture. The printing, die-cutting, gluing and folding are done in one operation on specially manufactured envelope machinery making it very cost effective.

For lower volumes printed from one up to four colours ready-made envelopes are overprinted on an offset printing machine. We use offset machinery specifically designed for printing envelopes.

For high and low volumes with complex print, heavy ink coverage or bleeds the design is printed onto flat sheets which are then die cut, folded and glued in three separate operations. As the process takes longer and there are more operations the price goes up accordingly.

We order reels of paper so that there is minimal waste during manufacture, the reel width is the size of the face of the envelope plus the size of the side seams. The reel of paper is loaded onto the envelope machine and threaded through to the delivery table at the end of the process. There is a splicer attached to the machine so that additional reels are joined automatically negating any requirement to rethread the paper. The paper is taken via a series of rollers through the following procedures:

The desired window size is cut by a flexible foil knife and the waste piece of paper is extracted. The window film, which has been ordered to the width of the window aperture plus additional film to allow for the glue to be applied, is purchased in reels. The window film is cut to the required size and glue is applied onto the edges of the window patch which is then stuck over the pre-cut aperture in the paper. The paper then runs through a series of heated dryers to ensure that all of the glue is dry.

Side Seams – the sides of the reel are then cut, folded and glued to form the envelope side seams. The paper then runs through a series of heated dryers to ensure that all of the glue is dry.

Cutting & Folding – a sever then cuts the reel of paper into individual envelopes which forms the flap and throat shape. The envelope are staggered and gum is applied to the flap. The envelopes run through a series of dryers to ensure that all of the gum is dry. The flaps are then folded down.

Final Delivery & Quality Inspection – there is an automatic counter which is set as required and the complete envelopes are delivered onto a table where they are packed into boxes and palletised. Inspections are carried out throughout the process by the staffs setting and operating the machines and by a team of quality inspectors.

Both internal (opaque/internal message to show through window) and external print requirements are applied via polymer printing plates. The paper then runs through a series of heated dryers to ensure that all of the ink is dry.

110 x 220mm

114 x 162mm

229 x 162mm

324 x 229mm